UL 325 Safety Standards

UL 325 Safety Standards are rules and regulations that must be followed in order to properly address the safety concerns and requirements needed for the automatic operation of all garage doors, vehicular gates, draperies, exterior awnings, louvers, windows and other opening and closing appliances rated 600 V or less. This standard was created by industry leaders working alongside Underwriters Laboratories (UL) with a primary goal of evaluating products in the interest of public safety, including the prevention of fire and electrical hazards.

By pairing with Underwriters Laboratories, the manufacturers of automatic operators are able to provide their consumers with safety requirements for all applicable products, as well as the ability to be tested at a nationally recognized testing laboratory. In order to comply with these standards, you must first be aware of the information needed regarding these UL 325 Safety Standards for safe and secure installation, usage and maintenance of all automated gate operators. The 7th Edition of the UL 325 Safety Standards, commonly referred to as UL 325-2018, is the latest revision of safety standards effective August 1st, 2018.

All gate operators manufactured on or after August 1st, 2018 must meet or exceed the most up-to-date standards for safety set forth by the 7th Edition of UL 325.

The Revised UL 325 7th Edition seeks to prevent accidents from happening and keep you and your loved ones safe. Some provisions include the clarification of select 6th Edition wording to avoid misinterpretation, the prohibition of tampering or bypassing key monitoring features, as well as adding manufacturer responsibilities for compliance. The notable 2018 changes to UL 325 are outlined below.

Key UL 325 Factors:

- Gate Operator Types and Classes

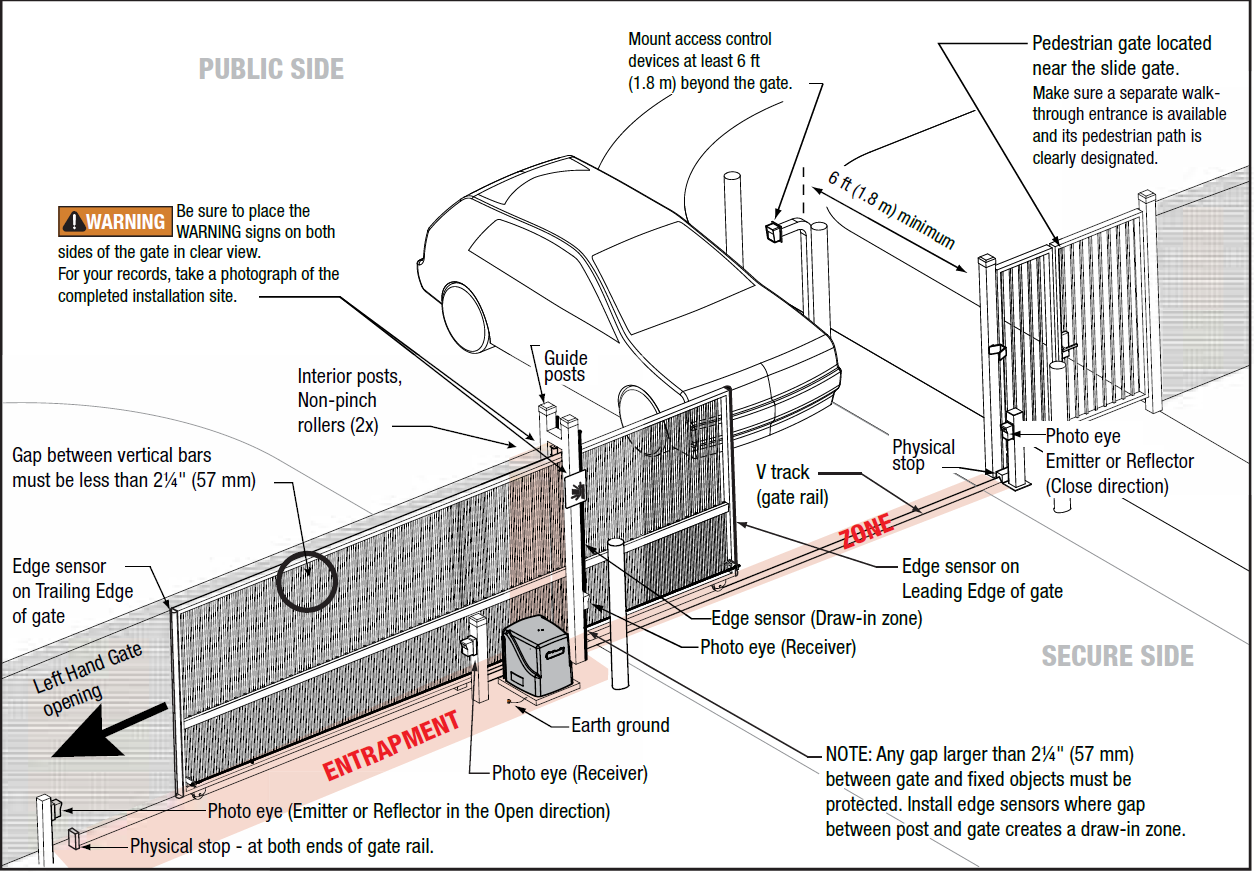

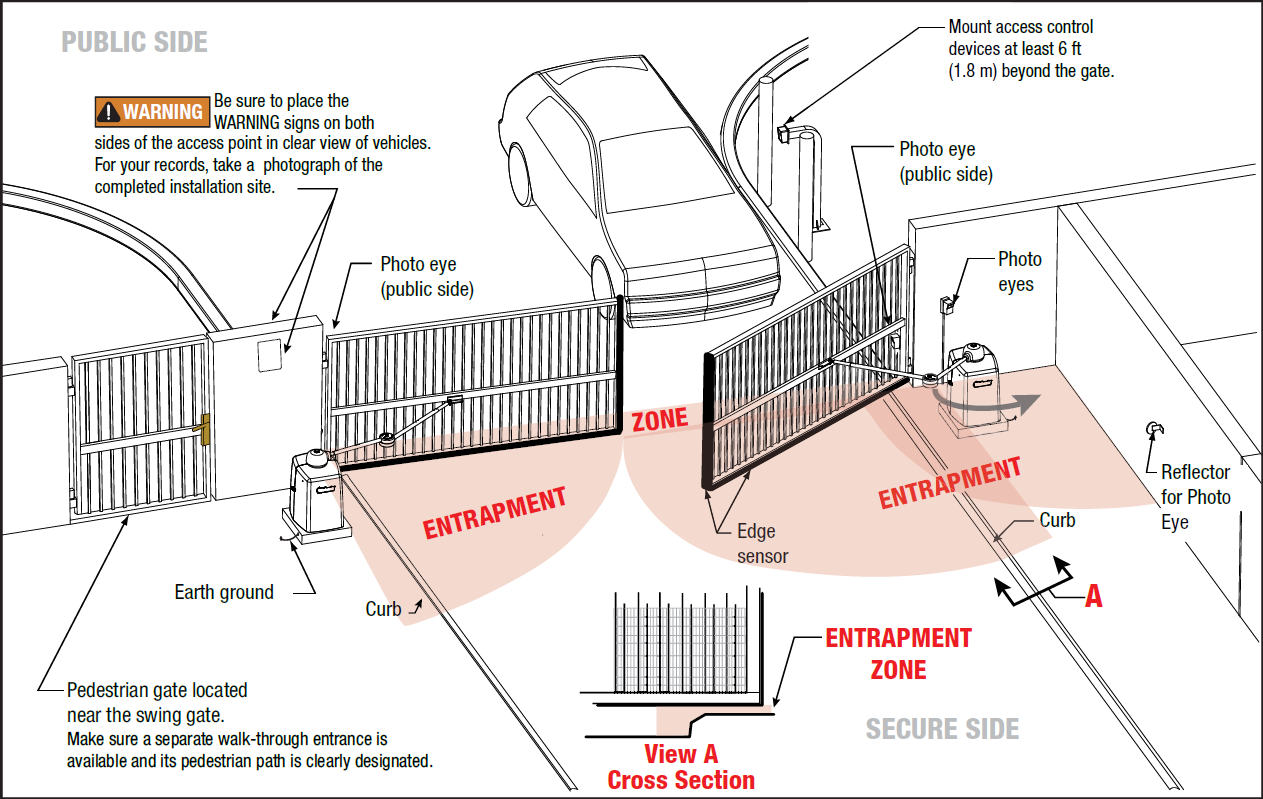

- Each Gate Operator Type's Defined Entrapment Zones

- Requirements For Gate Construction (Refer To ASTM F2200)

- Requirements For Gate Installation (Refer To ASTM F2200)

- Minimum Quantity of Entrapment Protection Devices

- All Installed External Entrapment Sensor Must Be Monitored

- Instructional Warning Requirements

- Safety Warning Requirements

- Manufacturers Install Any Components Required For Monitoring

*All Tampering or Work Around Techniques Are Strictly Prohibited. Including, But Not Limited To:

• Operator Modifications

• External Entrapment Protection Device Alteration

• Using or Suggesting Components With Intent To Bypass, Interfere With, or Overturn Monitoring Functions

• Resistors Are Prohibited From Being Provided With Operators or Installed Across Terminals That Are Made For Monitored Entrapment Devices

• Manuals Containing Instructions For Reprogramming, Reconfiguring, or Resetting Monitored Outputs That Do Not Comply With UL 325-2018

Gate Operator Classes

The latest revision to the UL 325 standard has introduced a classification for the different types of gate systems. Ideally, classifying the gate systems and their intended uses will allow for more clarity when adhering to safety standards. Each class has required types of obstruction sensing devices. The classes are as follows:

- Class I - Residential Vehicular Gate Operator: “A vehicular gate operator or system intended for use in garages or parking areas associated with a residence of one to four single families.”

- Class II - Commercial/General Access Vehicular Gate Operator: A vehicular gate operator or system intended for use in a commercial location or building such as a multi-family housing unit (five or more single-family units), hotels, garages, retail store, or other buildings accessible by or servicing the general public.”

- Class III - Industrial /Limited Access Vehicular Gate Operator: “A vehicular gate operator or system intended for use in an industrial location or building such as a factory or loading dock area or other locations not accessible by or intended to service the general public.”

- Class IV - Restricted Access Vehicular Gate Operator: “A vehicular gate operator or system intended for use in a guarded industrial location or building such as an airport security area or other restricted access locations not servicing the general public, in which authorized access is prevented via supervision by security personnel."

Gate Operator Category

| Horizontal Slide, Vertical Lift, and Vertical Pivot | Swing and Vehicular Barrier (Arm) |

| Entrapment Protection Types | Entrapment Protection Types |

| A, B1, B2, or D | A, B1, B2, C, or D |

| Entrapment Protection Types: | |

| Type A - Inherent Entrapments Protection System | |

| Type B1 - Non-Contact Sensor (Photoelectric Sensor or the Equivalent) | |

| Type B2 - Contact Sensor (Edge Device or the Equivalent) | |

| Type C - Inherent Force Limiting, Inherent Adjustable Clutch or Inherent Pressure Relief Device | |

| Type D - Actuating Device Requiring Continuous Pressure to Maintain Opening or Closing Motion of the Gate | |

| *The same type of device shall not be utilized for both entrapment protection means. Use of a single device to cover both the opening and closing directions is in accordance with the requirement. | |

Entrapment Protection Devices

In this context, entrapment is defined as the condition when an object is caught or held in a position that increases the risk of injury. The minimum number of external entrapment protection sensors required in a typical automated gate installation will depend on the type of operator, the type of gate, and the number of entrapment zones that require protection. At least two means of entrapment protection are required in each direction of travel for most installations. For any and all installations in which a direction has a risk of entrapment, at least two independent means of entrapment protection are required.

| Opening | Closing | |

| Horizontal Slide Gate | 2 | 2 |

| Horizontal Swing Gate | 2* | 2* |

| Vertical Pivot Gate | 2 | 2 |

| Vertical Lift Gate | 1 | 2 |

| *For a horizontal swing gate operator, at least two independent entrapment protection means are required in each direction of travel. Except, if there is no entrapment zone in one direction of travel, only one means of entrapment protection is required in that direction of travel; however, the other direction must have two independent entrapment protection means. | ||

ASTM F2200 Standards

The ASTM F2200 standard governs the construction of gates that are intended to be automatic gates. Therefore, the ASTM F2200 particularly emphasizes design and installation standards to essentially aid in meeting UL 325 standards. UL 325 and ASTM F2200 work cohesively to provide the general public with the highest level of safety. ASTM F2200 standards require that automated gates must have the following, where applicable:

• Guard Posts

• Protective Screen Mesh

• Covers For All Exposed Rollers

• Swing gates must not have any protrusions on the bottom of the gate

• Gates must be prevented from falling over if disconnected from the gate opener

• Swing gates with potential entrapment zones of greater than 4” to less than 16” must be protected

• Slide gates and the adjacent fence must not allow a 2 1/4” sphere to pass through up 48” from the ground

Slide Gates

• All exposed weight bearing rollers and pinch points that exist in less than 8 ft above grade must have covers.

• Gate must have fall-over protection to prevent the gate from falling when it is detached from supporting hardware.

• The physical gate stops to avoid over-travel in both directions.

• Proper adjustment of the inherent sensing system.

• No protrusions along the bottom of the gate.

• Protective screen mesh to guard openings from the gate's base support to a minimum height of 6 ft above the ground. This must prevent a sphere of 2.25 inches from passing under or through any opening in the gate or adjacent fence (the portion covered in the gate's open position).

Swing Gates

• Swing Gates used for vehicular traffic, operators must be installed

• Pedestrians must be directed to a separate entrance and exit

• The area of the gate must be designed so that people do not come in contact with it while it is in motion

• Signage to warn pedestrians to stay clear of the gate's path should be posted and be clearly visible

• Proper promotion of the separate pedestrian entrance and exit.

• No protrusions along the bottom of the gate.

• Fall over protection to prevent the gate from falling when the gate is detached from supporting hardware.

Safety Checklist

• Provide and Maintain Walkways and Signage to Direct Pedestrians to Separate Walk-Through Entrance

• Clearly Display Warning Signs on Both Sides of the Gate Where Vehicles Can See

• Gate Controls Should Not Be Operated or Played With By Children, Nor Should Children Have Access to Remotes or Transmitters

• All Access Controls Should Be Mounted At Least 6 ft Away From Moving Parts

Professional Installation

If a professional is installing your gate opener, he or she should provide you with a safe gate operating system. To ensure this safety, and to comply with the manufacturer's installation instructions and industry safety standards, your installer should present you with different options of certain safety devices that they feel are necessary to ensure a safe gate system. We STRONGLY suggest that you discuss these options with your installer and heed his or her recommendations regarding entrapment prevention devices and gate construction criteria. You should also refer to the manufacturer's installation manual for more information on the safety provisions and requirements of your particular vehicular gate system.

Gate Safety Installation Checklist